- info@biops.com.tr

- +90 538 441 64 94

- Mon - Sat : 08.00-21.00

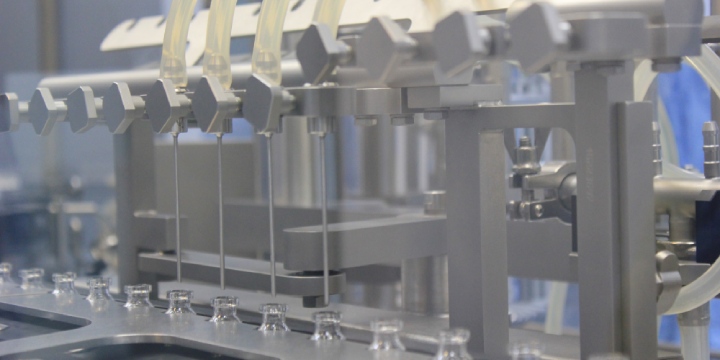

CLEAN ROOM VALIDATION

A clean room is a modular environment in which the following environmental factors are kept under control; temperature, airborne particulates, microbes, relative humidity, differential pressure, and airflow.

Clean room Validation is performed for a variety of reasons. To ensure that the design of the facility is fit for its intended purpose; to ensure that the facility, equipment, and environment meet User Requirement Specifications (URS); to ensure that the facility, equipment, and environment meet defined regulatory requirements; to ensure that the facility, equipment, and its environment function together as a system to meet defined standards.

The BioPS engineering team offers the following steps in the field of cleanroom validation to its clients:

• DESIGN QUALIFICATION

The purpose of this phase is to prove through objective evidence that the design is fit for its intended purpose. Design Qualification is a verification exercise against requirements defined in the acceptance criteria of your DQ protocol.

• INSTALLATION QUALIFICATION

(IQ) phase is to confirm through verification that equipment— as installed—confirms to user requirements and design requirements. Verification is focused on the following items that should be called for in your IQ protocol:

• OPERATION QUALIFICATION

The objective for this Operational Qualification (OQ) phase is to show through objective evidence that the cleanroom operates in conformance with design requirements and user defined requirements

• PERFORMANCE QUALIFICATION

The purpose of Performance Qualification (PQ) of the cleanroom is to demonstrate with objective evidence that the cleanroom consistently operates within defined parameters to produce the defined, desired environmental outcome. Cleanroom performance qualification involves testing and monitoring of the following:

• CLEANROOM CERTIFICATION

Validated cleanrooms are validated to a required class of cleanliness. The level of cleanliness chosen is driven by user requirements. (ISO 1464-1)

Join 60,000+ Subscribers and get a new discount coupon every saturday

Setting up and Optimizing Cultivation Processes on Large and Small Scales for the Pharmaceutical Company

08.00 am - 09.00 pm